The "sugar cane" decaffeination, at the heart of the Descafecol factory

All decaffeination processes must be synonymous with good quality coffees. The Descafecol factory in Colombia is one of the few companies that know how to decaffeinate coffee without denaturing it.

The Descafecol method

The Descafecol plant is located in Manizales, in one of Colombia's main specialty coffee-growing areas. Inaugurated in 1988, it is the only decaffeination plant in Colombia.

The Ethyl Acetate decaffeination process, derived from sugar cane

Sales Manager Mauricio Jaramillo and General Manager Sven Dabelstein explained how Ethyl Acetate works to extract caffeine. Ethyl acetate is a natural component of certain fruits, particularly ripe fruits.

Ethyl acetate, as a solvent derived from sugar cane, when used in the right conditions and quantities, is an excellent selective caffeine extractor.

The 6 stages of the Descafecol process

Steam treatment

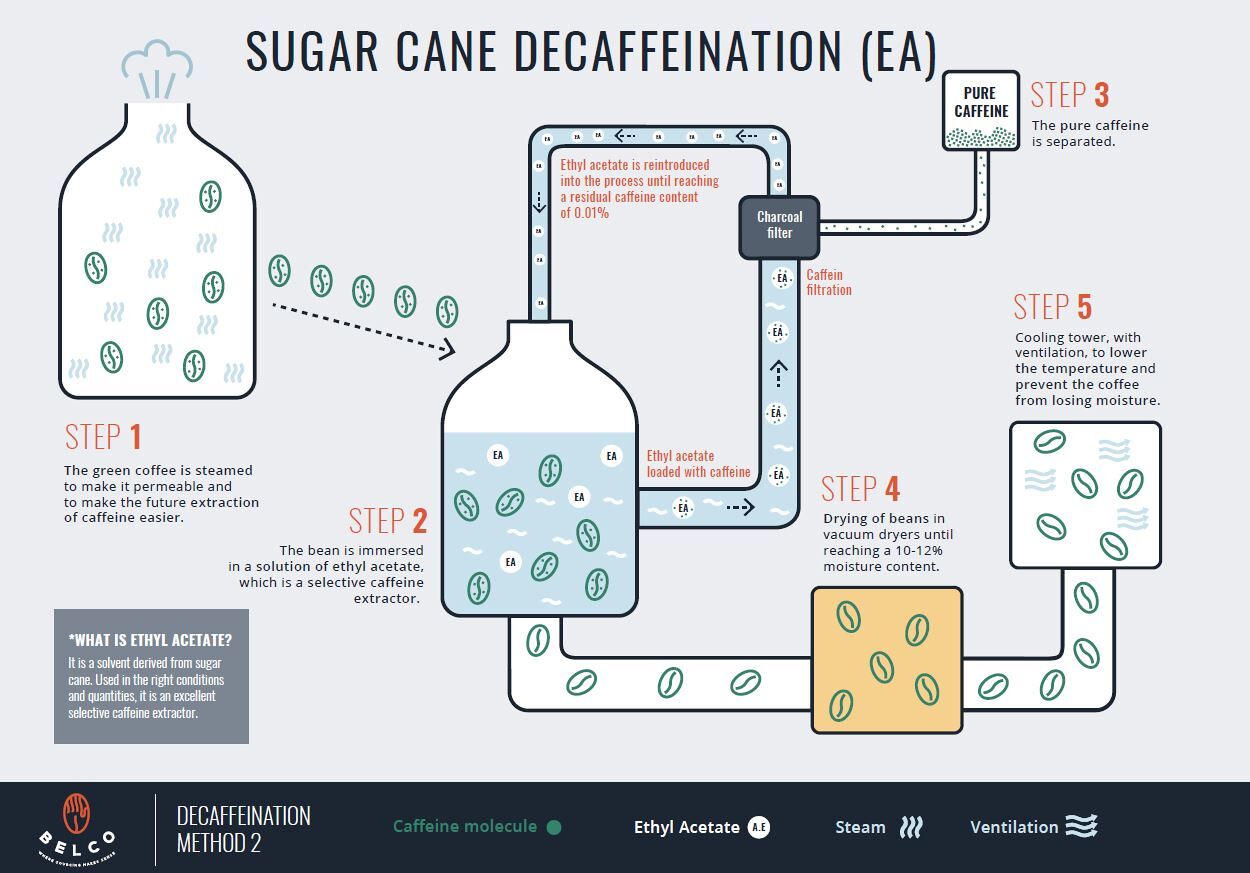

The first step is to expose the bean to a steam treatment designed to open the bean's membranes and facilitate future caffeine extraction.

Extraction

The bean is immersed in a solution of ethyl acetate, a selective caffeine extractor. The caffeine contained in the coffee bean then migrates to the liquid solvent, which is transported to another tank.

At this stage, the caffeine-laden ethyl acetate will be filtered and reintroduced to the process to further extract caffeine from the bean, down to 0.01% residual caffeine.

Separation of pure caffeine

The pure caffeine is separated.

Drying

The drying process takes place in vacuum dryers, ensuring rapid, even drying.

Cooling silo

The coffee is placed in a silo with ventilation to lower the temperature and prevent the coffee from losing moisture.

And finally...

Bean polishing

The "sugar cane" decaffeination, at the heart of the Descafecol factory

In addition to the decaffeination process, two types of quality control are carried out in their laboratory. The first consists of a physical and chemical analysis of the beans to measure the amount of residual caffeine, which, as a general rule, must not exceed 0.1%, and the Ethyl Acetate residue must not exceed 20 ppm.

In a second analysis, the organoleptic properties of the coffee are measured, comparing their profiles before and after the decaffeination process.

To conclude

Some extraction data

It should also be noted that these steps depend on time and a certain saturation of caffeine and wax in the liquid (EA). However, reuse will have its limits because, in the same Descafecol laboratory, the deterioration of its chemical structure will be analyzed and, depending on the results, its use or disposal will be defined.

What about residual caffeine?

The caffeine recovered in this process is of great value to the pharmaceutical industry. It is used in energy drinks, but also as a natural insecticide. At Descafecol, the caffeine recovered is natural, unrefined caffeine.

Organic coffee and the EA process

The question of using EA for organic coffee production has been discussed at length in the industry. Descafecol firmly asserts that EA is a totally natural component and can be used without concern for certified organic coffees.

Did you like this article? Share it with your community: